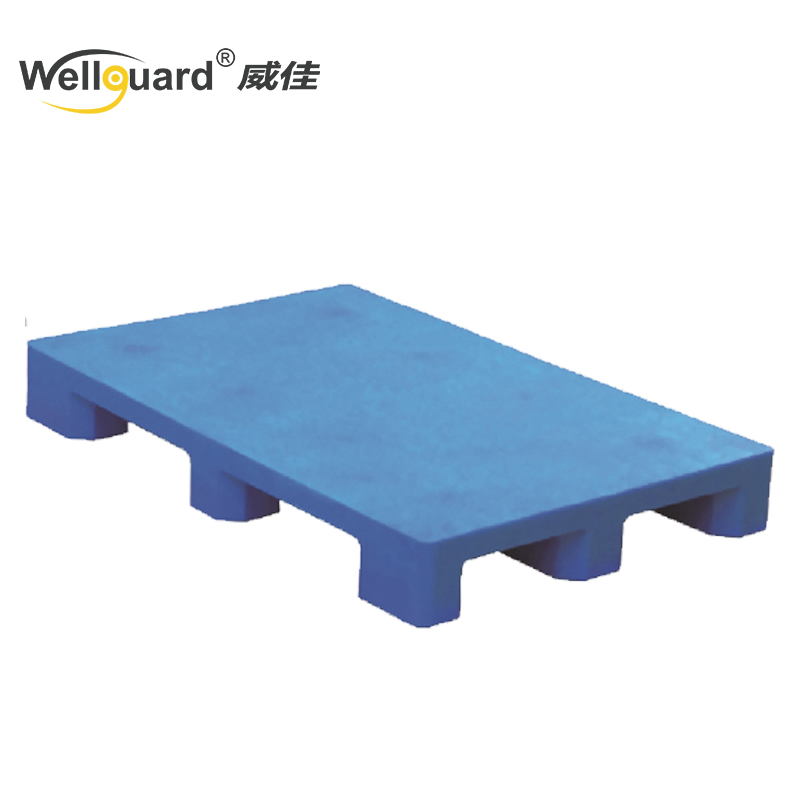

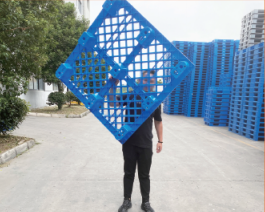

Nestable Plastic Pallets

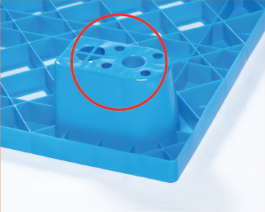

The bottom of Nestable Plastic Pallets is a nine-feet structure. The inside of the foot is equipped with horizontal and vertical cross ribs and thickened design. The pallet is not easily deformed after being hit by a forklift. There are water leakage holes at the bottom of the feet, which is easy to clean and will not accumulate water. The feet are tapered to allow pallets to be stacked on top of each other for centralized storage. The pallet occupies a small area and has low transportation costs, which is suitable for the storage of lighter goods and the turnover of unitized logistics transportation.

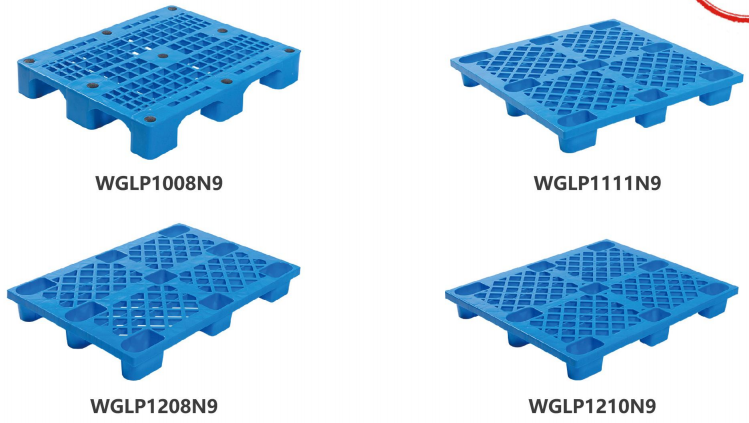

9-Feet Grid plastic pallet

9-Feet Grid plastic pallet |

Names | Numbers of Steel pipe | Dynamic loading(kg) | Static loading(kg) | Dimension (L*W*H/cm) | Forklift | Model |

1008-9 Feet Grid plastic pallet | 0 | 500 | 2000 | 100x80x14 | 4 WAY | WGLP1008N9 |

1111-9 Feet Grid plastic pallet | 0 | 500 | 2000 | 110x110x14 | 4 WAY | WGLP1111N9 |

1208-9 Feet Grid plastic pallet | 0 | 500 | 2000 | 120x80x14 | 4 WAY | WGLP1208N9 |

1210-9 Feet Grid plastic pallet | 0 | 500 | 2000 | 120x100x14 | 4 WAY | WGLP1210N9 |

1311-9 Feet Grid plastic pallet | 0 | 500 | 2000 | 130x110x14 | 4 WAY | WGLP1311N9 |

1210-18 Feet Grid plastic pallet | 0 | 700 | 3000 | 120x100x14 | 4 WAY | WGLP1210N18 |

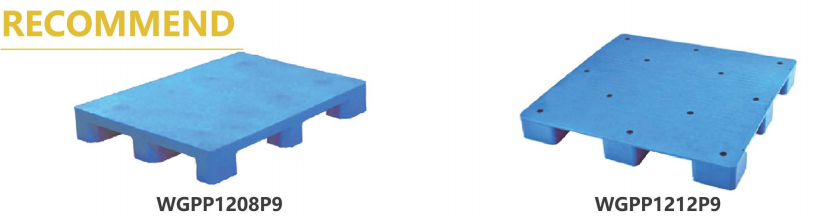

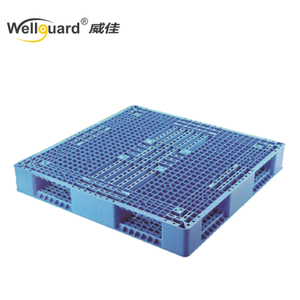

9-Feet Flat plastic pallet

9-Feet Flat plastic pallet |

Names | Numbers of Steel pipe | Dynamic loading(kg) | Static loading(kg) | Dimension (L*W*H/cm) | Forklift | Model |

1111-9 Feet Flat plastic pallet | 4 | 1000 | 4000 | 110x110x14 | 4 WAY | WGPP1111P9 |

1208-9 Feet Flat plastic pallet | 4 | 1000 | 4000 | 120x80x15 | 4 WAY | WGPP1111P9 |

1210-9 Feet Flat plastic pallet | 4 | 1000 | 4000 | 120x100x14 | 4 WAY | WGPP1210P9 |

1212-9 Feet Flat plastic pallet | 4 | 1000 | 4000 | 120x120x14 | 4 WAY | WGPP1212P9 |

1311-9 Feet Grid plastic pallet | 4 | 1000 | 4000 | 130x110x14 | 4 WAY | WGPP1311P9 |

Nestable Plastic Pallets’ advantages

Convenient and fast access from all sides

Plastic pallets are designed with forks on all sides to make the use of space more flexible to maximize the use of warehouse space.

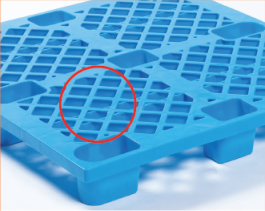

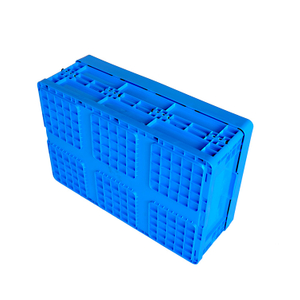

Grid hollow out Rib design

The hollow design on the surface is beneficial to the waterproof and moisture-proof of the goods to ensure that the bottom of the goods is in a ventilated state. The rib design improves the stability of the pallet and also improves the load-bearing capacity of the pallet.

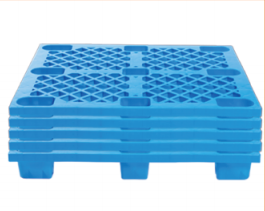

Stackable to save space

Some models can be stacked when not in use to save space.

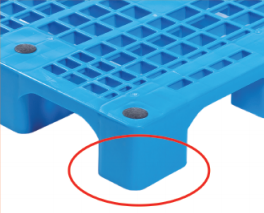

Pallet foot reinforcement design

Arc design of pallet feet

The interior is equipped with reinforcement ribs, which are impact-resistant and durable

Convenient for forklift use.

Reinforced leaky design

The bottom of the pallet has a water leakage hole design

Quickly remove stagnant water

Don't worry about water accumulation in the pallet

Meshone-sided light weight design

Lightweight, flexible and easy to carry

Convenient and time-saving operation

Improve the efficiency of cargo turnover.

Features of nestable plastic pallets

1. The stock product of the plastic tray is blue, and other colors such as red, yellow, green, black, gray, white can also be customized, the minimum order quantity is 500 pieces.

2. The product size error of plastic pallets is +3%, the weight error is +3%, the deformation rate of the side wall is ≤1%, the plane deformation of the pallet is not more than 5mm, and the change rate of the diagonal line of the pallet is ≤1%, all of which are within the allowable range of enterprise standards .

3. Adapt to the ambient temperature: -25C to +60C (try to avoid sun exposure and close to heat sources).

4. Raw materials: Ensure the use of new high-quality, high-strength modified PP or HDPE raw materials with good low temperature resistance and weather resistance, and never use recycled materials and recycled plastics or add calcium carbonate.

5. Quality assurance period. Under normal and reasonable use conditions, the product quality guarantee period is three years (36 months). If a damaged product is replaced by a new product of the same model due to damage that affects the reuse of the product, the supplier shall respond to any problems that occur during use. The problem has the obligation to maintain and eliminate it (it belongs to the quality problem of the product itself, except for the damage caused by human factors).

6. After the quality guarantee period or damage caused by human factors, free service is available. If you need to change parts, you will only be charged the cost of the minimum standard. If you need to change products, you will replace three damaged products with a new product of the same model. The freight is borne by the demand side.

7. Under normal use conditions (environment), the minimum service life of the pallet is 5 years. The annual damage rate of the pallet within 5 years is less than 1%. After 5 years, due to the natural aging of the plastic, the annual damage rate of the pallet will be greater than 1%. The number of turnovers of the pallet can exceed 10,000 times (if the pallet is damaged due to severe weather conditions, exceeding the load limit, equipment extrusion or man-made damage, it is not within the above range.)

When purchasing a suitable plastic pallet, the following factors need to be considered

1. The size and structure of the pallet, the packaging specifications of the goods and the way of placing them on the pallet;

2. The situation of pallet loading tools (such as 20 feet, 40 feet containers and trucks, etc.);

3. The situation of the pallet transport tool (such as forklift, stacker, hydraulic truck, etc.);

4. The structure, width and depth of the shelf (such as beam shelf, corbel shelf):

5. The load-bearing capacity, deflection, surface anti-skid coefficient and label position of the pallet, etc.;

6. One-time forming or two-time welding, for the consideration of cost and durability, the tray with one-time forming is preferred;

7. For general-purpose pallet sizes, such as 1210, 1208, 1111, 1311, 1411, 1412, etc., try to choose standardized products.